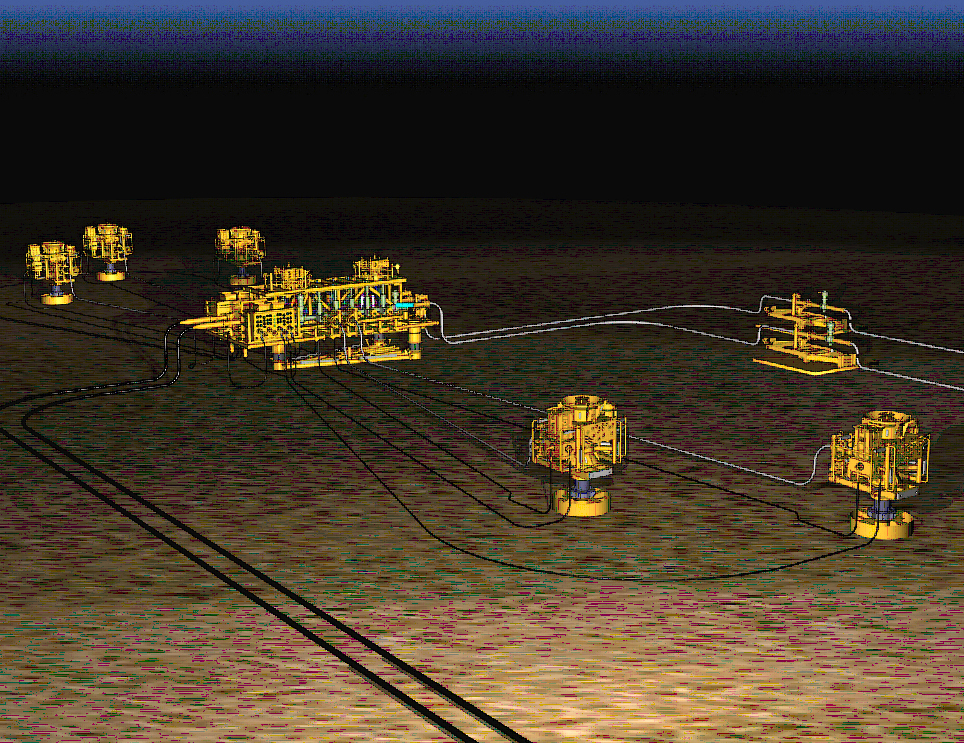

BP’s Taurus and Libra subsea fields are situated offshore Alexandria, Egypt and part of the larger West Nile Development in water depths of approximately 800 metres.

QA Weld Tech’s involvement with the West Nile Development stretches back for over 10 years, supplying both Xmas tree and manifold flowbends, fully clad with Corrosion Resistant Alloy, to our client OneSubsea.

Our involvement in this $12 million-dollar project continues with our client Subsea 7, supplying parts for the gas export tie in structures, including 24” tie- in pieces, transition pieces, stress joints and pipeline end terminations.

A full scope of weld procedure qualification, test rings and welder qualification has preceded fabrication to ensure the stringent specifications and quality standards of the project are met.

With in-house facilities ranging from right from shot blasting, weld overlay and CNC machining, through to pressure testing and bespoke packaging, we are able to project manage a broad work scope and ensure delivery timescales are met.